Laminating

It is the action of assembling surfaces, textile or not, continuously in order to create a multilayer material with new characteristics.

Example of characteristics : flexibility, thickness, color, hardness, shock absorption, comfort, etc.

Types of laminates

Laminating by calendering

Insertion of a hot melt surface (film/grid/web) or thermoplastic powder between two non-thermofusible layers. This assembly of materials passed between two heated rollers in order to melt the polymer layer which will pernerate the two other surfaces and act as a glue. This same technique can be used under a hot press action or on a cylinder equipped with a pressing belt.

Adhesive

Gluing by the application of a film or by spraying. This method consists in applying a glue (or a resin) directly on the fabric, under air action, it will polymerize in order to adhere to the textile surface. We can use synthetics or natural glues (ex : epoxy, acrylic, polyurethane, neoprene or latex). The multilayer then passes through a cold calender or is held under a flat press during the curing process.

Flaming

Bonding of a foam and another surface. Polyurethane or polyethylene foam is burned by flames and then deposited (continuously) on a textile surface. The foam under heat effect will act as a glue and adhere to the textile. Under flame effect, the foam loses its thickness.

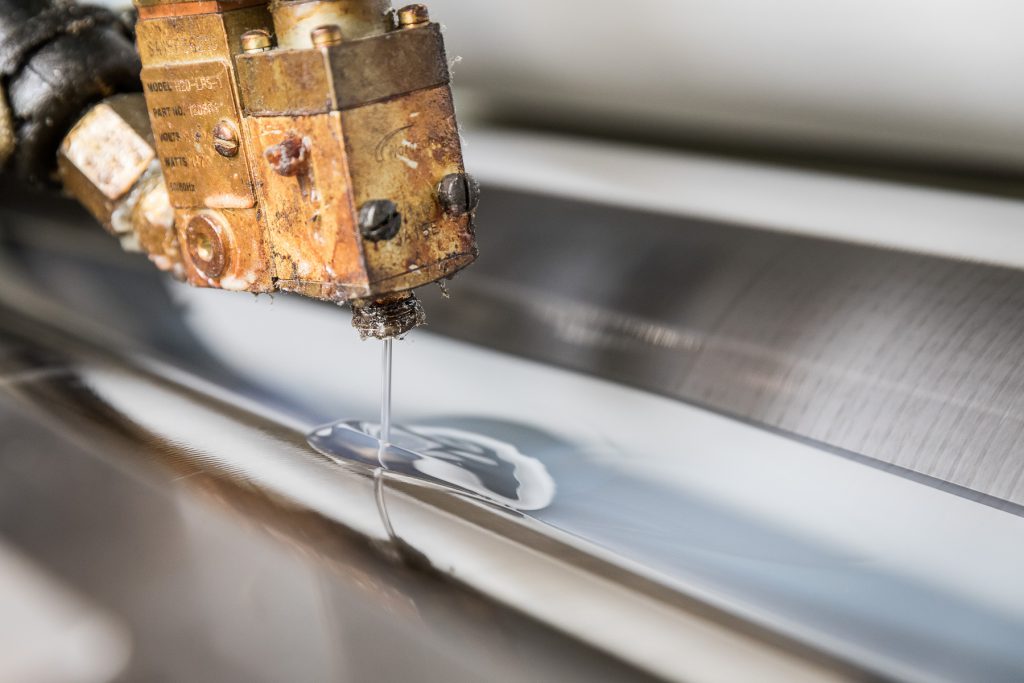

Hot melt gluing

Application of a hot glue between two surfaces, by a //lip nozzle// (glue flowing through a slit), of coating cylinders (engraved or not) or by a rotating screen (micro perforated cylinder with the desired pattern, similar to textile printing, the glue is inserted and scraped inside). It is also possible to spray the glue, by a spray or by atomization by compressed air (explosion of glue by air jets to create a kind of mist). The surface is then passed between two cylinders allowing the glue to penetrate deeply into the textiles to bind them.

Cold gluing

Deposition of adhesive in solution (glue liquefied by the action of a solvent) on a surface by the passage of a rotating screen (micro perforated cylinder with the desired pattern, similar to textile printing, the glue is inserted and scraped inside) or by spraying a glue in spray or by atomization by compressed air (explosion of glue by air jets in order to create a kind of mist). The surface is then passed between two rollers, allowing the glue to penetrate deeply into the textiles to bind them.

Types of fibers used

All surfaces can be heat-bonded. Some non-textile materials are also used, such as polyurethane foam, plastic films or metal grids.

Characteristics

Textile laminates characteristics depend on the method used and the field for which it is intended. Nevertheless, most multilayers allow the contribution of a damping or comfort property.

Applications

Automotive, clothing, sports cloth and sports equipment, medical, safety, PPE, etc.